Welding Nozzle Opening Machine

Welding nozzle opening machines are essential tools in industrial welding processes. These machines prepare the materials to be used in welding processes, and are an important step that determines the quality of the welding process. Welding nozzle opening machines have a wide range of applications in different industrial environments. The welding nozzle preparation process at the ends of metal sheets and pipes is carried out reliably thanks to the precise workmanship of the machines. These machines can automatically or semi-automatically perform processes such as cleaning, cutting, and correction of materials before the welding process, thus increasing work efficiency.

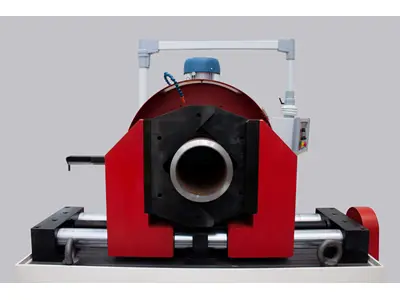

Pipe profile welding nozzle opening machine is a special machine that prepares the ends of metal pipes and profiles for welding. These machines allow the ends of pipes to be opened smoothly and accurately, enabling the welding process to be carried out more easily and safely. Widely used in industrial production and manufacturing sectors, these machines offer high productivity and quality standards.

Welding nozzle opening machines create a smooth welding surface by cutting the ends of pipes and profiles with high precision. These machines offer a wide range of material compatibility as they can be used with different metal materials such as steel, stainless steel, and aluminum. Welding nozzle opening machines, which can adapt to user needs with automatic and manual options, stand out with low energy consumption that reduces operating costs. With their robust and durable structures, they offer long-lasting use, providing an important advantage for industrial enterprises.

Instructions for Using Welding Nozzle Opening Machine

Using a welding nozzle opening machine requires following the correct technical steps in addition to safety precautions. First, put on all safety equipment and clean the work area before starting the process. Place the machine in the appropriate position for electrical connection and turn on the power button. Position and secure the material to be processed correctly.

Make the necessary process settings from the control panel on the machine; determine the cutting or opening depth, speed, and other parameters. Select the appropriate option from automatic or manual mode and start the process. The machine is designed to operate uniformly and smoothly on both sides of the material.

Carefully monitor the machine during the process and stop the operation in case of any problems or abnormalities. When the process is complete, turn off the machine and power source. Remove the processed material from the machine and clean if necessary. Perform regular maintenance on the machine, carry out periodic procedures such as lubrication, and follow other maintenance instructions specified by the manufacturer.

Welding Nozzle Opening Machine Prices

The price of a pipe profile welding nozzle opening machine can vary depending on many factors. The type of machine is one of the most decisive factors affecting the price. Automatic machines are generally more expensive as they require higher technology and less manual intervention. On the other hand, manual machines offer more economical options. In addition, features such as cutting accuracy, speed, and efficiency are important factors that affect the price. Machines that can cut with high precision and operate faster are generally more expensive. While machines with high energy efficiency reduce operating costs, they may require a higher initial investment.

The brand and warranty have a significant impact on the price. Machines from quality and reliable brands are generally more expensive. Machines that offer a long warranty period and a wide service network can also increase the investment cost. Therefore, the price of a pipe profile welding nozzle opening machine varies depending on many factors, and it is important to consider these factors to choose the most suitable machine for your needs. The average price range of a welding nozzle opening machine can be around {price range}.

To meet your need for a new or second-hand welding nozzle opening machine, you can purchase from reliable manufacturers or authorized suppliers through makinaturkiye.com and also seek support from authorized services.